Archives: Blog Articles

Description.

Power on – here’s how the Energy, Utilities & Resources sector faces evolving challenges

The industrial landscape is experiencing active reconfiguration the world over, not in the least due to evolving geopolitical realities, worthy initiatives by progressive Governments, and renewed market focus on energy transition and energy security. Everyone is clamoring for sustainable solutions and yet, there remains certain hurdles that may seem quite challenging and impossible to surmount if not for the tech solutions that meet these head-on.

Whilst the pressure mounts for energy transition and decarbonisation, hot on it is heels follows the demand-supply imbalance and market volatility, regulatory and compliance challenges, talent shortages, workplace evolution, and supply chain disruptions. Worst of all, rising costs, operational inefficiencies and cybersecurity threats also loom large in the big picture.

Where are we heading now?

Deloitte industry outlook predicted that in 2024, there will be an increasing reliance on artificial intelligence and other digital solutions to address the colossal challenges faced during energy transitions, especially grid transformation.

While companies scramble to adapt strategically to stay ahead of the curve, it is clear that the solution most seek now is incorporating Generative AI into their operational processes. This includes tools to inform and accelerate renewable project decisions, processes, configurations, and community engagement.

Other reliable and well-known solutions include embracing cloud technology and ERP systems.

To the rescue

The Energy, Utilities & Resources sector is at a crossroads right now. For those seeking timely solutions, innovative and resilient approaches are available. Leveraging digital transformation, fostering collaboration, and prioritising sustainability are great ways to remain relevant and ride the waves of change to a secure future.

How to leverage digital transformation? Simply by embracing the best solutions provided by reputed, trustworthy solutions providers. Be it cloud technology such as IFS cloud, (and ensuring you keep it regularly updated and tested as well as to enable your business processes can continue uninterrupted), to harnessing the inimitable power of AI to streamline your business operations with automated invoicing, and of course, specialised solutions for field service teams that promise practical success.

Would virtual power plants be the norm soon? Will at least 30% of the world population be able to embrace carbon-neutral practices? Will some of us move to Mars for better prospects? While only the future holds the answers, we can rest assured that industrial IoT will be working tirelessly to keep things running efficiently.

Platned joins expanding list of OmniByte Partnerships

[Fargo, ND] – OmniByte is excited to announce its full solution partnership with Platned. With Platned’s expertise in innovative business solutions and OmniByte’s powerful mobile forms platform, our shared commitment to excellence is perfectly positioned to deliver success to enterprise organizations globally. Together, we’ll enhance efficiency and drive growth, providing tailored solutions that meet the unique needs of each organization.

“Announcing our strategic partnership with OmniByte is a momentous occasion. This collaboration marks a significant milestone for our customers as we combine strengths to drive innovation and deliver unparalleled depth of solutions. Together, we will set new industry standards through the transformative experiences that we create. I much look forward to the journey together. Customer, OmniByte, and Platned as one.” said Chamara Arunoda, CEO, Platned.

Ray Berry, CEO of OmniByte commented: “At OmniByte, we believe collaboration drives innovation. Our partnership with Platned is a testament to our commitment to collaboration leading to unmatched solutions for our clients. Together, Platned’s expertise in driving innovation and delivering unparalleled depth of solutions paired with OmniByte’s cutting edge mobile platform technology will redefine what’s possible in the digital landscape.”

Key Highlights of the Partnership include:

- IFS Advanced Forms: Platned is now an official Solutions partner for this industry leading digital forms solution that seamlessly integrates to IFS Cloud, IFS FSM, MWO, IFS Apps 10 and other IFS solutions.

- FormsPro: OmniByte’s flagship product—a smart, digital forms solution that enterprise organizations are using to streamline the process of collecting data for their mobile workforce. Platned is a Reseller and Solutions partner for FormsPro.

This partnership marks a new chapter in delivering transformative results for both organizations and most importantly transformative solutions for our mutual customers.

About OmniByte:

At OmniByte, we empower enterprise organizations to effectively and efficiently manage complex business processes through the digital collection and reporting of data. OmniByte’s smart digital forms solutions—FormsPro and IFS Advanced Forms empower organizations with a mobile workforce to capture data at the point of service driving informed AI results powering intelligent business decisions. No other mobile forms platform offers the same depth and breadth of functionality and deployment options. We deliver solutions and services designed to improve your organization’s daily operations while providing integration to your current and future business solutions. OmniByte is a North American based organization proudly headquartered in Fargo, ND.

Learn more by visiting www.omnibyte.com.

Navigating growth: How to scale without losing your start up ‘spirit’

In today’s rapidly evolving business landscape, maintaining agility while scaling is no small feat.

Throughout my career, I’ve had the privilege of being part of several startups – helping new companies grow and evolve into larger, more structured organisations. While growing pains are inevitable, many can be minimised or even avoided if you continually try hard to keep hold of the advantages in being small and flexible. i.e. probably the very same things that helped you to start on the road to success in the first place.

The real challenge in management lies in determining which aspects of that early-stage agility can continue to set you apart from the competition and which can be adapted as the company scales. With increased business size comes the inevitable need for a larger and more structured organisation, and more customer-facing roles, yet you always want everyone to retain the approach and the ‘hands on’ touch of the people who started the organisation and defined the ‘culture’ that your customers seem to like.

The initial management team can no longer be involved in all aspects of the operations; new managers need to develop and grow themselves, but whilst not losing the personal touch and approach which the first customers liked and trusted. And trust is probably the key word in successfully managing such growth. The senior management team has to trust the new managers to develop the company in the right way – within the guidelines they are given. Trust them to continually question the need for complexity over simplicity and process over agility. In moments of uncertainty, they should always choose the path that preserves the trust of both existing and future customers and employees.

@Platned is a prime example of a company very successfully navigating these challenges. As they continue to grow—doubling in size each year over the last 3-4 years—they’ve maintained the trust and respect that characterised and defined the early days of the company. This trust has been a cornerstone of their ability to evolve as they grow – offering great opportunities to new employees and future managers, whilst also retaining their customers by continually providing them with the same levels of flexible and trusted support. Loyal customers from around the world who have trusted us to grow with them. Customers like @Wellness Pet Food, @Sumi Agro, and @Mid West Ports. Long may it continue!

These lessons resonate strongly with the journey of every business striving to scale up without losing touch with the very essence of what initially made them successful. It’s a constant effort, but when done well, the rewards are tremendous.

Optimising supplier payment automation with integrated AI in Process Workflow Management

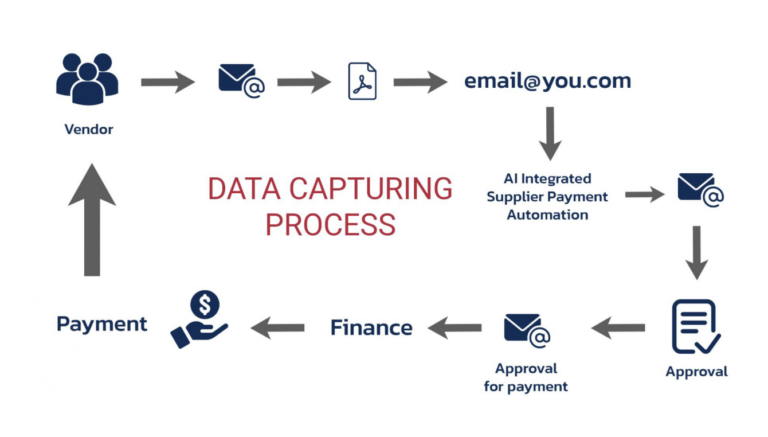

For Accounts Payable (AP) departments, navigating the ever-growing pile of invoices can be a time-consuming and error-prone process. Manual data entry, delayed approvals, and the risk of duplicate payments all contribute to inefficiencies and frustrations. Thankfully, process workflow management with integrated Artificial Intelligence (AI) offers a powerful solution to streamline supplier payment automation and achieve a new level of control.

What is Process Workflow Management?

Process workflow management involves mapping out the entire supplier payment process, from initial invoice receipt to final payment. This map defines each step, assigns clear roles and responsibilities, and establishes a logical flow for efficient processing. This clarity ensures consistency, accountability, and transparency – all critical elements for minimising errors and maximising efficiency within your AP team.

Introducing the AI to supercharge your workflow

By integrating AI into your process workflow management system, you unlock a suite of intelligent capabilities that significantly enhance workflow automation and streamline operations. Here’s how AI transforms your supplier payment workflows:

- Machine learning marvels: Manual data entry becomes a relic of the past. AI, powered by machine learning algorithms, can automatically extract data from invoices with remarkable accuracy. From vendor information and invoice details to line items, AI captures it all, eliminating human error and saving countless hours.

- Automated approvals for routine transactions: No more chasing signatures for commonplace purchases. AI analyses invoices based on pre-defined rules, automatically triggering approvals for routine transactions. This frees up your team to focus on exceptions and complex invoices requiring human expertise.

- Enhanced accuracy through continuous learning: AI algorithms are constantly learning and improving. This ongoing refinement minimises the occurrence of missed payments or duplicate invoices, leading to smoother financial management and enhanced control over your cash flow.

- Real-time visibility: gaining control over every step: Gone are the days of wondering where an invoice stands in the payment process. With AI integration, you gain real-time visibility into every stage. This allows you to track invoice status, identify potential bottlenecks, and ensure timely payments to your suppliers, fostering positive and productive relationships.

Platned’s AI integrated Supplier Payment Automation

Platned’s AI Integrated Supplier Payment Automation has been specifically designed to automate parts of the manual Accounts Payable process, streamlining your workflow and saving valuable time. Here’s how our system empowers you:

- Automated Data Capture:

Our AI engine utilises advanced machine learning to capture values directly from your PDF invoices. This eliminates the need for manual data entry and minimises errors.

- Automatic Recognition and Processing:

Say goodbye to data entry delays. Platned automatically recognises invoice details and sends them for further processing within your workflow.

- Intelligent Approvals:

Free your team from routine tasks. Our system automatically triggers electronic invoice verifications and authorisations based on predefined rules you set.

- Flexibility for Exceptions:

While automation is key, we understand that exceptions occur. Our system allows for manual invoice entry if required.

- Enhanced Reporting:

Gain valuable insights into your AP processes. We offer report generation with the ability to export reports as CSV files for further analysis.

- Centralised Control:

Maintain complete oversight with our admin module. This module allows you to control system operations and ensure everything runs smoothly.

- Actionable Alerts:

Our intelligent alerts notify your team of any pending actions within the workflow, ensuring timely processing.

By leveraging Platned’s AI Integrated Supplier Payment Automation, you can unlock all the benefits mentioned earlier and experience an even more streamlined and efficient AP operation.

The Tangible Benefits of AI-Powered Process Workflow Management

Integrating AI into your process workflow management system offers a multitude of benefits for your AP department:

- Increased Efficiency: Eliminate tedious manual tasks and streamline the entire payment process, freeing up valuable staff time for more strategic initiatives.

- Reduced Risk of Errors: AI minimises human error in data entry and approval processes, leading to improved data accuracy and reduced financial risks.

- Improved Cash Flow Management: Automation of payments and real-time visibility into your financial situation empowers you to make informed decisions regarding cash flow management.

- Enhanced Vendor Relationships: Timely payments and improved communication fostered by AI-powered automation lead to stronger relationships with your suppliers.

- Strategic Insights: Gain valuable data and insights into your spending habits, enabling you to make data-driven decisions and optimise procurement processes.

Embrace the Future of Payment Automation

Don’t let manual processes and data entry bottlenecks hinder your AP department’s effectiveness. Embrace the power of process workflow management with integrated AI. With Platned, you can design, automate, and optimize your supplier payment workflows for unparalleled efficiency and control.

Are you ready to transform your AP operations and unlock the future of streamlined supplier payment automation?

Navigating Sri Lanka’s Tech Industry: Essential Insights for Undergraduates

This blog is a guide for undergraduates and anyone aspiring to work in the tech industry.

This article delves into the dynamic landscape of Sri Lanka’s IT sector, exploring emerging trends, key skills in demand, and the exciting opportunities that lie ahead.

Emerging trends in Sri Lanka’s IT sector

The IT industry in Sri Lanka is poised for significant growth, with projections indicating it will become a $3 billion industry by 2024. This growth is driven by export revenue, entrepreneurship, innovation, and digital adoption, creating over 300,000 direct jobs and enabling 1,000 startups in the country. The government’s focus on regulatory reforms and foreign direct investment has positioned Sri Lanka as an emerging hub for IT and IT-enabled services (ITeS).

Key Skills in demand

In today’s digital era, staying updated with the latest technologies and trends is crucial. Sri Lanka’s IT sector demands proficiency in emerging fields such as artificial intelligence, cybersecurity, and data science. Additionally, the rise of digital platforms and remote work has increased the need for skills in software development, data analytics, and digital marketing. To stay competitive, students must embrace lifelong learning and continuously update their technical skills.

Importance of soft skills

Technical skills alone are not sufficient. The ability to communicate effectively, work in teams, and solve complex problems is equally important. Soft skills are often the differentiators that set successful professionals apart in the IT industry. Employers are increasingly looking for candidates who can demonstrate strong interpersonal skills and the ability to adapt to changing environments.

Networking: building professional connections

Networking plays a pivotal role in career development. Building a strong professional network can open doors to new opportunities and provide invaluable support and guidance. Engaging with industry professionals, attending conferences, and participating in online forums are effective ways to expand one’s network and stay connected with industry trends.

Gaining practical experience

Hands-on experience is essential for applying theoretical knowledge and developing real-world skills. Internships, projects, and practical training programmes provide invaluable exposure to the IT industry’s working environment. Such experiences not only enhance technical skills but also build confidence and professionalism.

Embracing change and innovation

The IT industry is constantly evolving, with new technologies and methodologies emerging regularly. Being adaptable and open to change is critical for success in this dynamic environment. Professionals who embrace change and continuously seek innovative solutions are better equipped to navigate the challenges and opportunities in the IT sector.

The future of Sri Lanka’s IT industry is promising, as long as the future tech workforce is capable of meeting the industry’s requisites. By staying updated with industry trends, developing both technical and soft skills, building strong networks, gaining practical experience, and embracing change, these future IT professionals will be well-prepared to thrive in the ever-evolving IT landscape. I believe universities and colleges should provide career guidance to all tech undergraduates throughout their courses, helping them to stay in tune with market demands.

IFS Implementation in 2024: A Step-by-Step guide for modern businesses

A robust Enterprise Resource Planning (ERP) system like IFS is no longer a differentiator, but a necessity. However, a successful ERP implementation requires a well-defined roadmap that considers not just best practices, but also leverages latest technologies for improved efficiency and growth flexibility.

With a robust suite of ERP Services and team of highly skilled experts, we usually take a systematic step-by-step approach to ERP implementation using IFS. To eliminate roadblocks and make sure the system remains future-proof, our approach makes space to integrate all the future technologies into the IFS system.

Our step-by-step guide to navigate IFS implementation in 2024

Take a look at Platned’s Implementation Roadmap to successfully implement IFS into your business. As the forerunners of the ERP Industry, we’ve included the industry’s best practices along with the modern day integrations that help you and your company evolve and grow smoothly without disruptions.

1. Define your business goals and needs

The cornerstone of a successful ERP implementation with IFS lies in establishing clear and measurable objectives. Begin by conducting a thorough business process analysis. This analysis should involve in-depth discussions with key stakeholders across various departments – finance, operations, sales, and marketing – to identify pain points, areas for improvement, and future growth aspirations. Align your IFS ERP implementation with these specific goals, ensuring the chosen modules and functionalities directly address your needs.

Embrace the power of AI and ML

Consider how emerging technologies like artificial intelligence (AI) and machine learning (ML) can be integrated with IFS to unlock new levels of efficiency and performance. Explore how AI-powered automation can streamline repetitive tasks like data entry and order processing, freeing up valuable employee time for strategic initiatives.

Investigate the potential of ML to enhance forecasting accuracy by analysing historical data and identifying trends. By integrating these cutting-edge technologies with IFS, you can gain deeper insights from your data, optimise decision-making, and gain a competitive edge.

2. Assemble your IFS ERP implementation dream team

Building a strong and collaborative team is crucial for navigating a successful IFS implementation. This team should be a cross-functional group, comprised of:

- Internal Stakeholders: Representatives from various departments who will be utilising IFS on a daily basis. Their involvement ensures the system caters to their specific needs and workflows.

- IT Specialists: In-house IT professionals with a strong understanding of your existing infrastructure and expertise in data migration and system configuration.

- External IFS Consultants (Recommended): Experienced IFS consultants can provide invaluable guidance throughout the ERP implementation process. They can offer industry best practices, assist with customisation, and ensure a smooth transition.

Pro tip: Introduce a Change Manager or Change Coordinator

Consider including a dedicated “Change Manager or Change Coordinator” in your implementation team. This individual should be a strong communicator with a deep understanding of both the current business processes and the functionalities of IFS. They will be responsible for promoting user adoption of the new system, addressing any resistance to change, and ensuring a smooth transition for all employees. They must prioritise change requests, assess their impact, and accept or reject changes.

3. Choose the right IFS Deployment Model that aligns with your business needs

There are several IFS deployment models available, each with its own advantages and disadvantages. Here’s a breakdown of the most common options:

- On-Premise deployment: This traditional model involves installing and managing IFS software on your own servers. It offers greater control over the system but requires significant upfront investment in hardware and IT expertise.

- Cloud-Based deployment: This model leverages a cloud provider’s infrastructure to host and manage the IFS application. Cloud deployments are becoming increasingly popular due to their scalability, reduced IT burden, and automatic access to the latest updates and features.

- Hybrid deployment: This combines elements of both on-premise and cloud deployments. It offers a balance of control and flexibility, allowing you to keep sensitive data on-premise while leveraging the cloud for other functionalities.

In recent years we’ve witnessed a significant rise in Cloud-based IFS deployments. Here’s why.

Cloud-based IFS deployments offer:

- Scalability: Cloud-based solutions can easily scale up or down based on your evolving company’s needs, eliminating the need for costly hardware upgrades or management.

- Reduced IT Burden: Cloud providers handle infrastructure maintenance and software updates, freeing up your IT team to focus on core business initiatives.

- Accessibility: Cloud-based IFS can be accessed from anywhere with an internet connection, facilitating remote work and improved collaboration.

We suggest you carefully evaluate your budget, IT resources, security requirements, and future growth plans to determine the deployment model that best aligns with your specific company’s needs.

4. Data Migration and System Configuration: Building the Foundation for Accuracy and Efficiency

Data migration is the process of transferring existing information from your current systems to IFS. This step is crucial for ensuring the ERP system has accurate and complete information to function effectively. Here’s how we navigate this stage:

- Data Mapping and Cleansing: Before migration, we map your existing data structure to the corresponding fields in IFS ensuring smooth transfer and minimising errors. Additionally, we consider cleansing techniques to identify and rectify any inconsistencies or inaccuracies in your existing data.

- Leveraging Data Governance Best Practices: In 2024, governance best practices are essential for successful data migration. That is why, we establish clear data ownership, implement access controls, and define quality standards. This ensures data integrity within IFS and empowers you to make informed decisions based on accurate information.

- System Configuration: Once the migration is complete, we configure IFS to meet your specific needs. This involves customising workflows, defining user permissions, and activating relevant modules.

Pro tip: Always consider future scalability

When configuring the system in 2024, consider future scalability. Opt for configurations that can easily adapt to accommodate growth in data volume, users, and business complexity. This will minimise the need for reconfiguration down the line.

5. User training and change management

Equipping your team with the necessary skills to navigate IFS effectively is paramount. Invest in comprehensive user training programs tailored to the specific roles and responsibilities of each department.

Include modern learning techniques

In 2024, explore e-learning modules, microlearning content, and gamified training approaches. These techniques offer flexibility, cater to different learning styles, and increase user engagement and knowledge retention.

Furthermore, remember the importance of change management. Change can be disruptive, so proactively address potential resistance to the new system. Utilise your “Change Manager or Change Coordinator” to address concerns, provide ongoing support, and encourage user adoption.

6. Testing and go-live

Before launching IFS into full production, we recommend a thorough testing. This involves:

- Unit testing: Testing individual functionalities of the system to ensure they work as intended.

- Integration testing: Verifying seamless data flow between IFS and other existing business systems.

- User Acceptance Testing (UAT): Real users from various departments test the system to ensure it meets their needs and workflows.

In 2024, user acceptance testing (UAT) is a critical step. During UAT, identify and address any bugs, usability issues, or inconsistencies in the system before going live. This ensures a smooth transition for all users and minimises disruption to daily operations.

7. Continuous improvement and post-go-live support

A successful IFS ERP implementation is not a one-time event; it’s an ongoing process. Here’s how to maximise your investment after go-live:

- Monitor system performance: Regularly monitor system performance metrics like uptime, response times, and user activity. Identify areas for improvement and optimise configurations as needed.

- Leverage new features and updates: Stay updated with the latest IFS releases and consider implementing new features that can further streamline your operations or address emerging business needs.

- Invest in ongoing support: Consider ongoing support plans from IFS or a trusted partner. These plans can provide access to updates, expert advice, and readily available resources to help your team maximise the long-term value of IFS.

By following these steps and embracing modern approaches, you can ensure a smooth and successful IFS ERP implementation in 2024. Remember, a well-integrated ERP system can transform your business operations by:

- Increasing efficiency: IFS streamlines processes, automates tasks, and facilitates data-driven decision-making, leading to improved efficiency and productivity. Employees are empowered to focus on strategic initiatives rather than manual tasks.

- Enhancing collaboration: IFS fosters seamless collaboration across departments and facilitates real-time information sharing. Improved visibility into inventory levels, project progress, and customer data empowers teams to work together effectively and achieve shared goals.

- Boosting visibility: IFS offers a comprehensive view of your entire business operation, providing valuable insights into key performance indicators (KPIs) across departments. This data-driven approach empowers you to make informed decisions, identify areas for improvement, and optimise resource allocation.

- Gaining a competitive edge: A well-implemented IFS ERP system can give your business a significant competitive edge. Improved operational efficiency, enhanced collaboration, and data-driven decision-making can lead to faster response times, increased customer satisfaction, and improved profitability.

Remember, a successful IFS implementation is a journey, not a destination. By adopting a modern approach, fostering a culture of continuous improvement, and leveraging the expertise of your team and trusted partners, you can unlock the full potential of IFS and transform your business for success in 2024 and beyond.

How ERP systems enhance Inventory Management in Manufacturing

Manufacturing is a fast-paced segment of any industry. Efficient inventory management is the only difference between smooth operations and costly disruptions. ERP (Enterprise Resource Planning) systems act as the central nervous system of a manufacturing operation. Their impact on inventory management is nothing short of transformative. At Platned, our expert ERP consultants have witnessed how these systems can revolutionise inventory management. Here’s a closer look at how ERP systems empower manufacturers to achieve optimal inventory control:

1. Real-time visibility: from raw materials to finished goods

ERP systems provide real-time visibility into your entire inventory lifecycle. From raw materials entering your manufacturing facility to finished goods ready for shipment. This includes:

- Inventory Levels:

Track stock levels across all locations, including warehouses, production lines, and in-transit goods. - Material Requirements Planning (MRP):

ERP systems automatically forecast material needs based on manufacturing schedules and sales forecasts. This ensures you have the right materials at the right time. - Work-in-Process (WIP) Tracking:

Monitor the progress of unfinished goods through various production stages. This leads to better capacity planning and reduced lead times.

This comprehensive overview empowers informed decision-making. You can identify potential stockouts before they occur & optimise ordering schedules. This helps avoid overstocking, and ensure a smooth flow of materials throughout the manufacturing process.

Our experienced ERP consultants have implemented these for our clients. And we’ve seen this visibility transform the way our clients manage their inventories. Therefore leading to more efficient operations and happier customers.

2. Streamlined Procurement and Replenishment

ERP systems automate manual procurement tasks, saving valuable time and reducing errors. Here’s how:

- Automated Purchase Orders:

ERP systems trigger automatic purchase orders when inventory levels reach predefined thresholds. This eliminates the risk of human error and ensures timely replenishment. - Vendor Management:

Manage supplier relationships and track purchase orders with ease. ERP provides insights into vendor performance so you can build strong supplier relationships and negotiate better terms.

By automating procurement processes, ERP streamlines your supply chain, reduces lead times. Now you have the materials you need to fulfil customer orders on time.

3. Improved Demand Forecasting and Production Planning

Accurate demand forecasting is crucial for maintaining optimal inventory levels. ERP integrates sales data, historical trends, and market forecasts to predict future demand with great accuracy. This information feeds into:

- Production Planning:

ERP systems help you plan production schedules based on forecasted demand. This in turn helps you produce the right goods at the right time to meet customer needs. - Inventory Optimisation:

By understanding future demand, you can optimise inventory levels & avoid overstocking or stock-outs. This reduces storage costs, improves cash flow, and ensures efficient resource allocation.

With improved demand forecasting, ERP systems enable manufacturers to be more responsive to market fluctuations and customer needs. All while minimising the risk of holding excess inventory. Our production planning strategies in ERP systems have exemplified how accurate demand forecasting can transform efficiency & help our clients stay ahead of the curve.

4. Enhanced Quality Control and Traceability

Maintaining product quality is paramount in manufacturing. ERP systems facilitate quality control by:

- Lot Tracking:

Track materials and finished goods throughout the process. Now you can identify the source of any quality issue and take corrective action immediately. - Compliance Management:

Ensure compliance with industry regulations and quality standards by tracking processes and materials used.

ERP systems provide a comprehensive audit trail for all materials and products. This also facilitates traceability and ensures the highest quality standards are met consistently. Platned’s implementations have helped numerous companies maintain top-tier quality control, safeguard their reputations and ensure customer satisfaction.

5. Reduced Costs and Increased Profitability

ERP systems lead to significant cost savings across the manufacturing value chain. It can optimise inventory levels, streamline procurement processes, and improve planning. Here’s how:

- Reduced Storage Costs:

Minimise the need for excess inventory, reducing storage requirements and associated costs. - Lower Procurement Costs:

Optimise purchase orders and negotiate better deals with suppliers, leading to reduced procurement costs. - Improved Efficiency:

Streamlined production processes and reduced lead times contribute to increased efficiency and overall profitability.

The Bottom Line

ERP is a game-changer for manufacturing inventory management. They provide real-time visibility, streamline processes, and empower data-driven decision-making. This in turn leads to increased efficiency, reduced costs, and ultimately, improved profitability.

At Platned, we’ve seen firsthand how ERP can transform manufacturing operations. Our expertise in implementing and optimising ERP systems ensures that our clients achieve the best possible outcomes, driving their businesses toward greater success and sustainability. That is why we say, investing in an ERP system is an investment in the future of your manufacturing operations.

Optimising Your IFS Investment: A Guide to Choosing the Right IFS Consultancy Partner

As a sales Director with over a decade of experience in enterprise solutions, I have come to appreciate the critical role of selecting the right partners in maximising the potential of our investments. Among the myriads of decisions we face, choosing the ideal consultancy partner for your IFS investment stands out as one of the most crucial. In this blog post, I’ll share my insights and advice on navigating this process effectively.

Investing in IFS solutions is a strategic move for any organisation looking to streamline operations, enhance productivity, and drive growth. However, the success of such an investment often hinges on the expertise and support provided by an IFS consultancy partner.

Here are some key considerations to keep in mind when selecting the right partner for your organisation:

Experience and Expertise: Look for a consultancy partner with a proven track record of success in implementing IFS solutions. Experience matters, especially in complex ERP projects. Ensure that the partner has a team of seasoned professionals with deep expertise in IFS consulting and enterprise solutions. A partner with extensive experience across various industries will bring valuable insights and best practices to the table.

Specialisation in IFS: Not all consultancy firms are created equally. Choose a partner that specialises specifically in IFS consulting. While general enterprise consulting firms may offer a wide range of services, they may lack the depth of knowledge and expertise required for successful IFS implementations. A dedicated IFS partner will have a thorough understanding of the platform’s intricacies, enabling them to deliver tailored solutions that meet your organisation’s unique needs.

Collaborative Approach: Effective collaboration between your organisation and the consultancy partner is essential for a successful implementation. Look for a partner that prioritises collaboration and communication throughout the project lifecycle. They should be willing to listen to your requirements, offer proactive guidance, and work closely with your team to ensure a seamless implementation process.

Proven Methodology: A structured and proven methodology is critical for ensuring the success of an IFS implementation. Inquire about the consultancy partner’s approach to project management, implementation, and post-implementation support. A partner with a well-defined methodology will help mitigate risks, minimise disruptions, and ensure that the project stays on track and within budget.

Commitment to Long-Term Success: Choose a consultancy partner that is committed to your organisation’s long-term success, not just the immediate implementation. Look for a partner that offers comprehensive post-implementation support, including training, maintenance, and ongoing optimisation services. They should be invested in helping your organisation derive maximum value from your IFS investment over the long term.

References and Testimonials: Don’t just take the consultancy partner’s word for it. Seek out references and testimonials from their past clients to get a sense of their reputation and the quality of their work. Ask specific questions about their experiences working with the partner, including project outcomes, communication effectiveness, and overall satisfaction.

Cultural Fit: Last but no means least, consider the cultural fit between your organisation and the consultancy partner. A strong cultural alignment will facilitate smoother collaboration and ensure that both parties are working towards the same goals. Look for a partner that shares your organisation’s values, work ethic, and commitment to excellence.

In conclusion, choosing the right consultancy partner is a critical step in optimising your IFS investment. By considering factors such as experience, specialisation, collaboration, methodology, long-term commitment, references, and cultural fit, you can select a partner that will support your organisation’s growth and success with IFS solutions. Remember, the right partner can make all the difference in the success of your IFS implementation journey.

Empowering Sri Lanka’s IT Future: Platned’s Commitment to Talent and Growth

Having had the pleasure (and honour) to be at the recent opening of Platned’s impressive new offices in Colombo, it got me thinking again about the importance of Sri Lanka in the development of so many successful IT companies.

I’ve now been involved in three such companies in the ERP industry (going back across more than 25 years) and each one has both enjoyed, and massively benefitted from, the incredible pool of skilled and committed talent that the Sri Lankan education system continues to provide.

Platned is led by four guys, all born and initially educated in Sri Lanka – before they each went abroad to develop their careers and pursue their dreams. This latest investment is about showing their personal commitment to giving something back to the community and the free education system that gave them their start – by investing more, in order that even more people can embark upon a similar road.

The new offices will help accommodate the significant expansion that Platned expects over the next few years (including a doubling of the number of staff members in Colombo), and expand the pool of people able to support our customers across the globe. But there are also further investments planned in the necessary training and the crucial collaboration with a number of academic institutions in the city. Platned are also trying to coordinate more with other IFS Partners in our market, to see if we can work better together and more efficiently develop the skills of the young people emerging from the Sri Lankan education system.

Platned (like others) have already benefited tremendously from the number of skilled young people available in Sri Lanka, but now is the time for us to really acknowledge this and give something more in return – so that this source of supply can not only be sustained but grow even further. Helping the Sri Lankan economy to develop more students and in doing so also support more companies in our market space.

Choose the right software that fits your business

When considering which software to use for your business, it is crucial to prioritize the longevity of the product. Using software that has reached its end-of-life can pose significant challenges and risks, making it an unfavourable choice for your organization. Here’s why:

- No More Updates: When software reaches its end-of-life, the vendor no longer provides updates, security patches, or bug fixes. This leaves the software vulnerable to security threats and other issues that can disrupt your business operations.

- Compatibility Issues: Outdated software may become incompatible with newer systems and hardware, hindering integration and collaboration with partners who use newer software.

- Lack of Technical Support: When software reaches its end-of-life, the vendor no longer offers technical support, making it difficult to troubleshoot issues and find timely resolutions.

- Reduced Functionality: Outdated software lacks the features, functionality and offers for new systems, limiting your business capabilities and competitiveness in the industry.

- Increased Costs: Continuing to use outdated software can lead to higher costs in the long run. The lack of support and updates may make maintenance more challenging and resource-intensive.

- Evergreen Solution: No end-of-life date, ensuring continuous support and updates. 24/7 Managed and Support Services.

- Ongoing Partnership: We forge enduring partnerships with our customers.

It’s crucial to evaluate the long-term costs and risks associated with using end-of-life software. While it may seem cost-effective initially, it can ultimately result in increased expensed and downtime. Opting for regularly updated and supported software provides your business with the tools to succeed and grow.

The decision to replace one software system with another typically depends on several factors, including the functionality and features of the current system, the specific needs of the customer, the costs and benefits of the replacement, and the technical compatibility and requirements of the new system.

Customers may choose to replace their current software with a new system if the current system no longer meets their needs, if it is outdated or unsupported, or if it is no longer compatible with other software systems used by the customer. They may also choose to replace a system if a new system offers additional features or benefits that the current system does not have.

At Platned, we have extensive experience in implementing ERP solutions across various industries and specialized in Equipment Rental Industry, Construction Industry, Service Industry, Manufacturing Industry and Complex MRO. Share your challenges with us, and we’ll be eager to assist you in overcoming them.

Our Solution includes:

Cross-Industry and Cross-ERP Knowledge: We bring diverse expertise to address your unique requirements.

Let Platned help you transition to a reliable and future-proof solution. Contact us today!

Contact Platned: https://platned.com/contact-us/

Written by: Rukshan Berman (https://www.linkedin.com/in/rukshan-b-bab9a22a/)